Now Providing Technical Support for Mining Wearhouse

We are now proudly providing technical support for Australian based supplier for aftermarket parts, Mining Wearhouse.

We are now proudly providing technical support for Australian based supplier for aftermarket parts, Mining Wearhouse.

Engineering Technical Paper Chrome-white iron (CWI) has been the work-horse wear material for hard-rock and mineral-processing pumps for more than 70 years. The paper traces the

Mining pumps often fly under the radar as an opportunity to reduce carbon emissions, but the impact of improving pump efficiency can be huge.

We saw this first hand recently, with a large remote mineral processing plant in Western Australia.

A nickel mine in Western Australia wanted to extend the life of shaft sleeves on their mill circuit pumps.

They were using OEM shaft sleeves manufactured from cast iron. These sleeves had to be scrapped after each wear campaign due to severe erosion and corrosion frequently encountered in sites with corrosive flush water. Severe leakage occurred prior to each shut, leading to environmental and safety concerns.

A Western Australian nickel mine struggled with frequent mill pump rebuilds, achieving just 600 hours of wear life on critical wet-end components. By partnering with 7D Team, they implemented engineered pump solutions featuring high chrome wear parts, a redesigned impeller, and an upgraded shaft seal.

Here’s a sneak peek at what we’ve been working on: a revolutionary new slurry and liquor seal that requires NO EXTERNAL FLUSH, does not require leakage for cooling, and is NOT a mechanical seal, gland packing or expeller.

A Lithium mine in Western Australia were experiencing a disruptive three week maintenance shut cycle due to severe wear on 6/4DD-AH pumps.

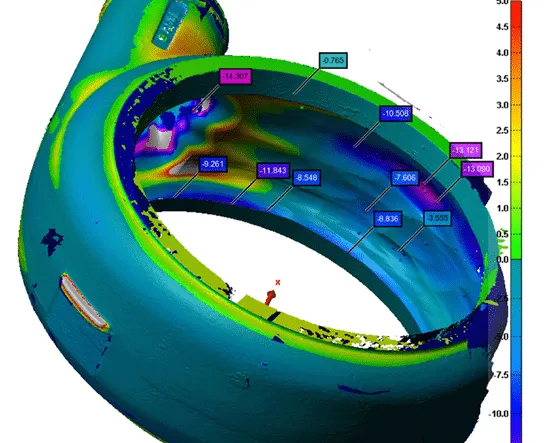

A refinery operating in Western Australia recently approached us to improve and redesign an under performing old pump, as it over its years of operation, process needs had changed. To achieve the desired outcome, very close collaboration was needed between our firms.